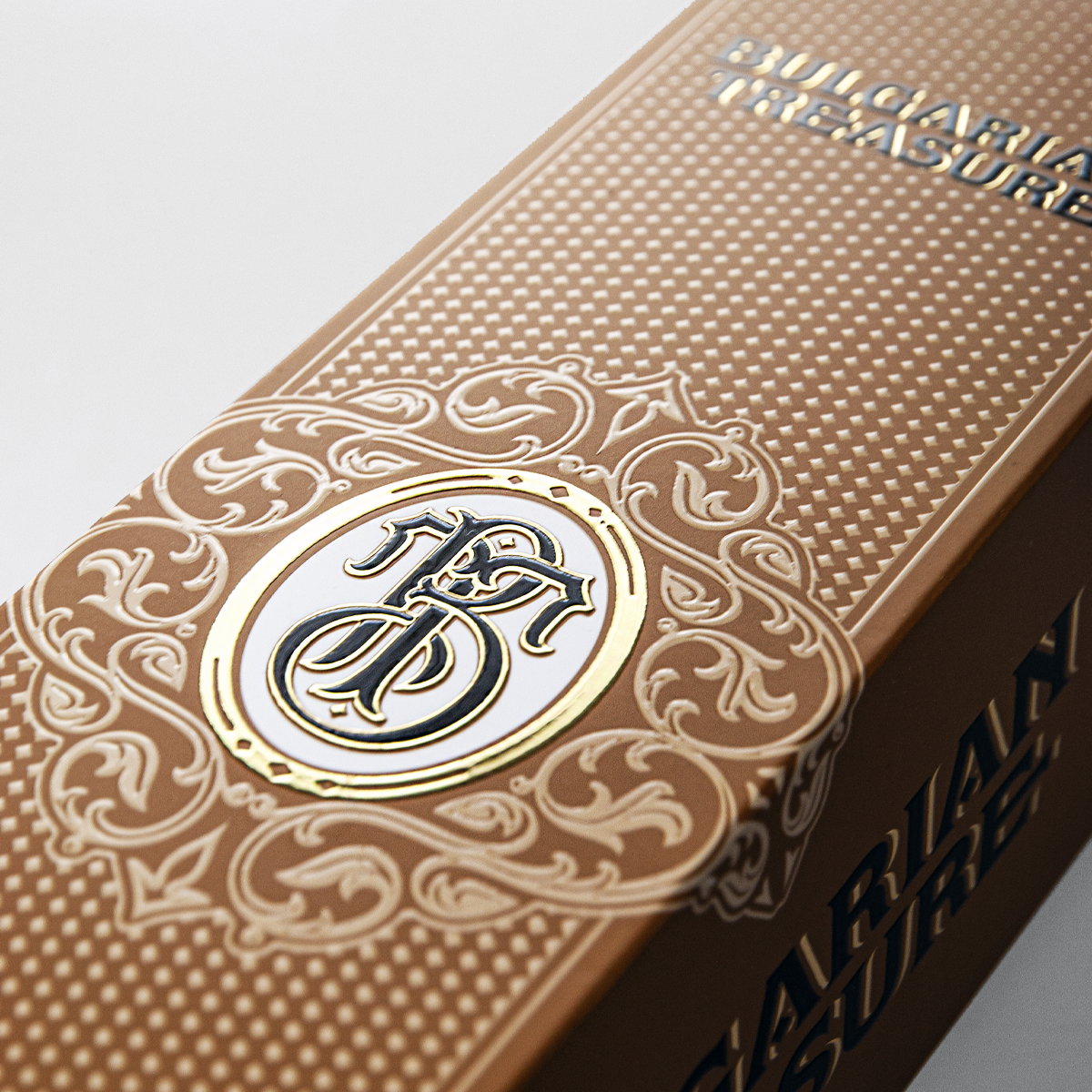

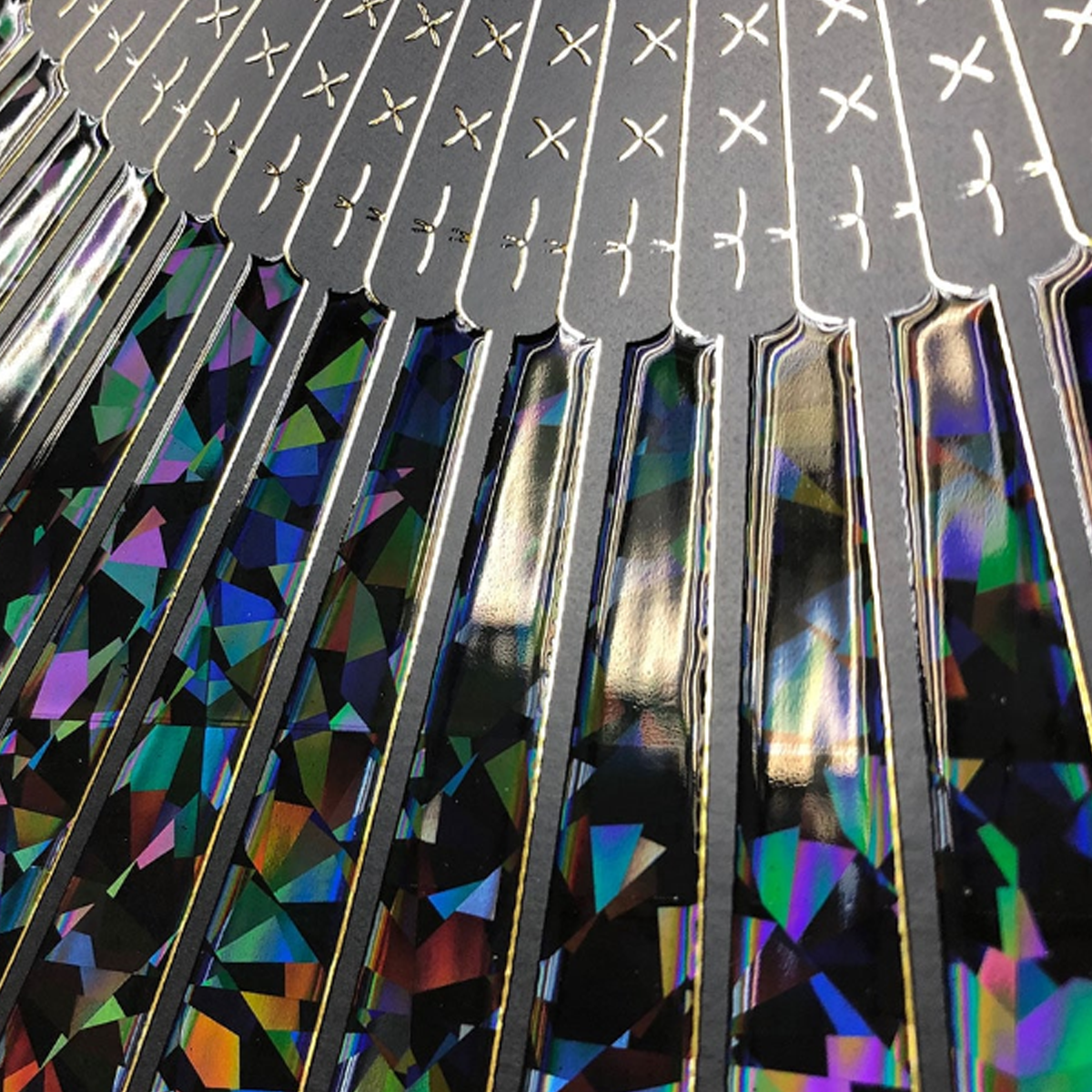

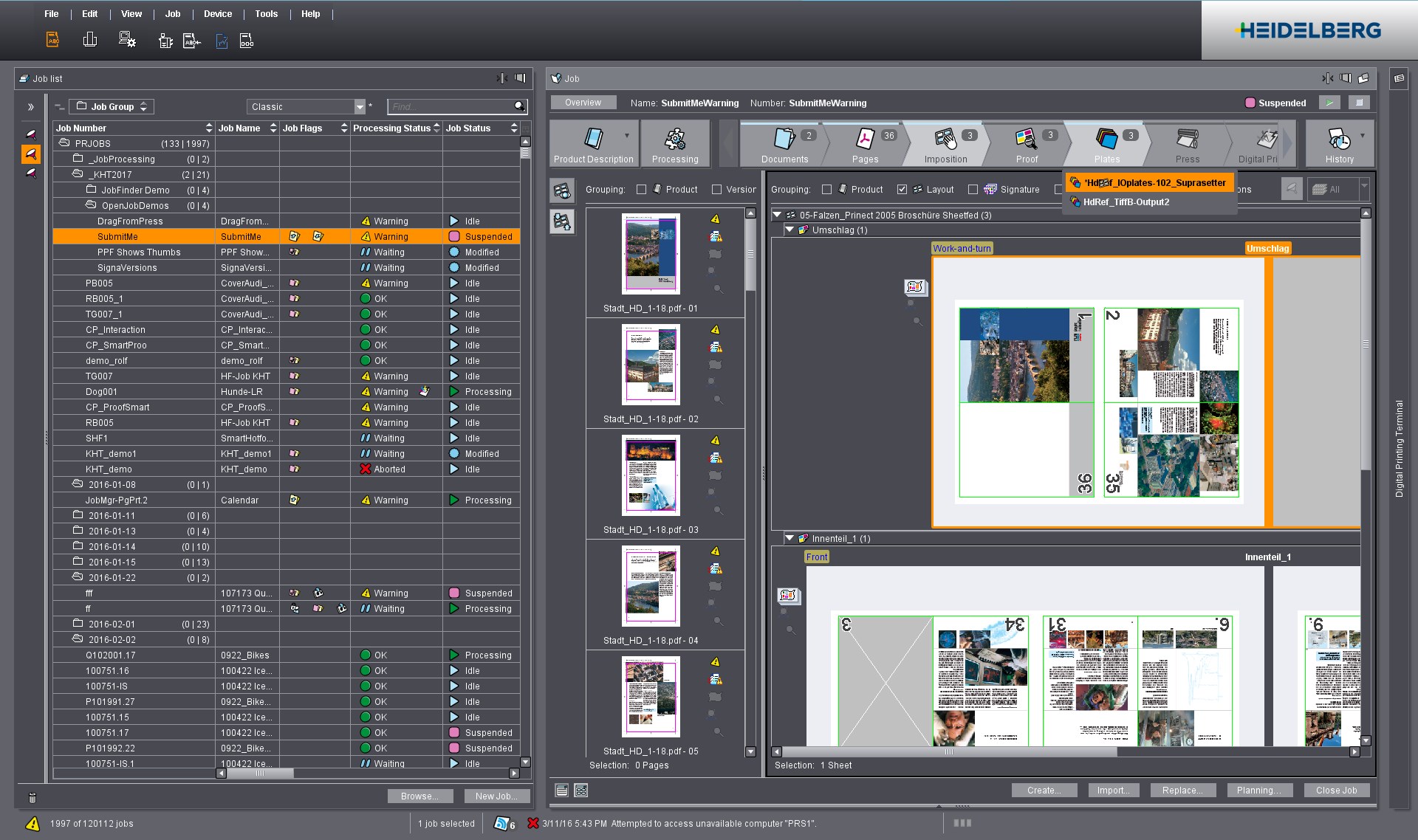

J Point Plus' three HP Indigo Digital Presses provide excellent print quality with options for 7-color printing. The printers are compatible with wide range of media with high productivity - supports more than 3,000 certified media (papers and cardboards with different texture and density, metallic foils, canvas, sticker papers, PVC materials). The technology implemented by HP Indigo Digital Presses enhances the digital offset printing process and guarantees printing of highest quality. With HP Adaptive Half-toning technology, they provide super fine and precise printing, suitable for the production of advertising materials in small and medium runs.

HP Indigo 10r Digital Press

- Image resolution: 812 and 1219 dpi at 8 bit, addressability: 2438 X 2438 dpi HDI (High Definition Imaging)

- Sheet size: 530 x 750 mm max

- Image size: 510 x 740 mm max

- Special effect inks: UV red, light cyan, light magenta, white, digital matte

- Mode HP IndiChrome off press (IMS): achieving up to 97% of the PANTONE® color range

- Thick substrate kit: up to 460 microns

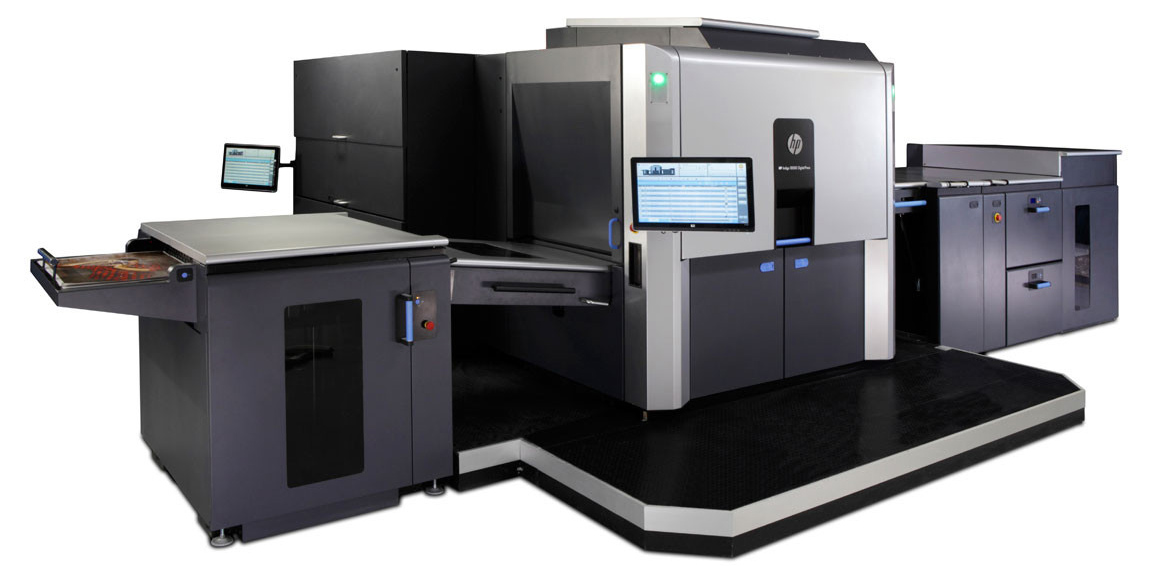

HP Indigo 5600 & HP Indigo 3550 Digital Presses

- Image resolution: 812 and 1219 dpi at 8 bit, addressability: 2438 X 2438 dpi HDI (High Definition Imaging), 812 x 1624 dpi HDI (for HP indigo 3550)

- Sheet size: 330 x 482 mm max

- Image size: 317 x 450 mm max

- Colors: 7-color printing in HP IndiChrome mode (CMYK + orange, violet, white)

- Special effect inks: UV red, light cyan, light magenta, white, digital matte

- Mode HP IndiChrome off press (IMS): achieving up to 97% of the PANTONE® color range

- Thick substrate kit: up to 460 microns

- One Shot process kit: allows printing on PVC and synthetic media using the technology HP Indigo One Shot Color